In-depth Look at the Three-Layer Floor Structure for Food Trucks

2025-09-24

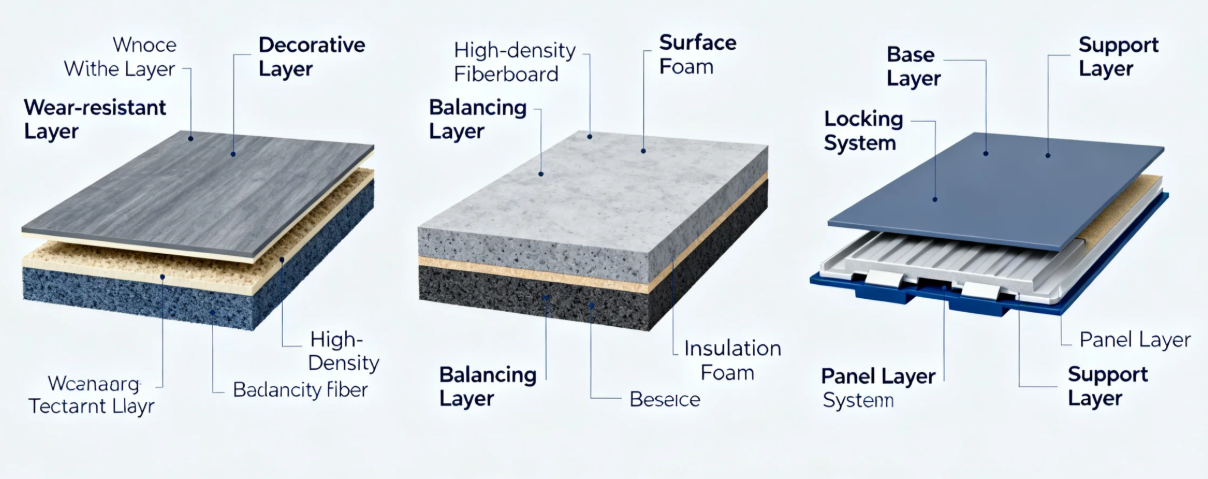

The three-layer floor for food trucks is a structural laminated board specifically designed for mobile catering equipment. It is composed of a wear-resistant surface layer, a middle support layer, and a moisture-proof base layer. Its compact structure offers advantages of durability, easy cleaning, and quick installation.

Typically, the surface layer is treated with high-strength coatings to enhance wear resistance and anti-slip properties; the middle layer uses lightweight, high-density materials to provide stability and partial thermal insulation; the bottom layer integrates with the vehicle frame, serving moisture-proof and shock-absorption functions. This three-layer structure significantly enhances the food truck's service life and operational efficiency for users.

Qingdao Oriental Shimao Import And Export Co., Ltd. is an enterprise specializing in producing customized mobile food trucks, supplying core components including three-layer floors, stainless steel kitchen equipment, and power systems. We can produce three-layer floor structures suitable for small coffee trucks, large fast-food trucks, and multi-functional catering trailers, meeting operational needs in various scenarios.

At Oriental Shimao Food Truck Manufacturing, our professional team designs and optimizes three-layer floor solutions based on customer usage scenarios, with experience gained from years of collaboration with F&B entrepreneurs. Our products have been exported to Southeast Asia, Europe, America, etc., providing reliable support for street food, festival markets, mobile coffee shops, and more. We are committed to building long-term relationships with distributors and end-users.

Content Guide

1.What is the purpose of the three-layer floor in a food truck?

2. What are the three common types of three-layer floors?

3. What is the load-bearing capacity of the three-layer floor?

4. What material options are available for the three-layer floor?

5. Is the maintenance cost for the three-layer floor high?

6.What is the approximate cost for a custom three-layer floor?

7. How to choose a food truck with a three-layer floor?

1. What is the purpose of the three-layer floor in a food truck?

The three-layer floor is a key structural component of food trucks, with main functions including:

Wear Resistance & Slip Prevention: Special surface treatment enhances safety, adapting to environments with oil, water, etc.

Structural Stability: The middle layer supports the weight of kitchen equipment, reducing the risk of deformation caused by road vibrations.

Moisture Proofing & Insulation: The bottom layer blocks ground moisture and helps maintain internal temperature.

Applicable Scenarios:

Fast-food trucks, coffee trucks, and other high-frequency mobile operations

Outdoor markets, festival events requiring quick setup

Long-term use in high-temperature and high-humidity environments

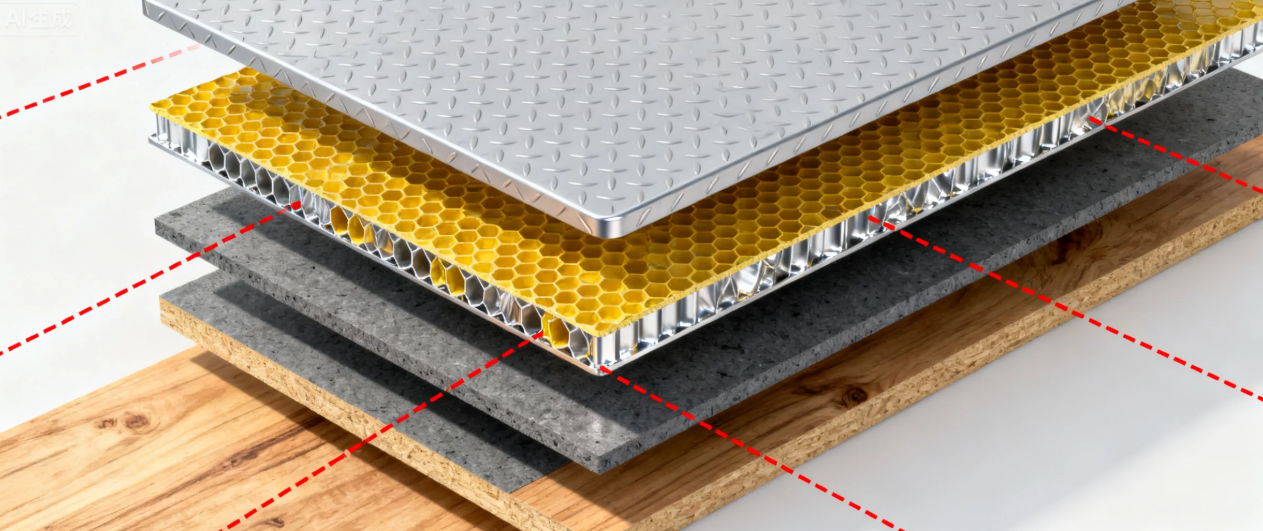

2. What are the three common types of three-layer floors?

1.Based on material and process differences, they are mainly divided into:

Composite Reinforced Type: Features a wear-resistant steel plate surface, high-density wood middle layer, and galvanized moisture-proof bottom plate, suitable for heavy-duty food trucks.

2.Lightweight & Insulated Type: Uses an aluminum-magnesium alloy surface + honeycomb structure middle layer, offering light weight and good thermal insulation, ideal for small new energy food trucks.

3.Quick-Disassembly Type: Modular design with snap-fit connections between surface and bottom layers, facilitating later maintenance or replacement, suitable for rental food trucks.

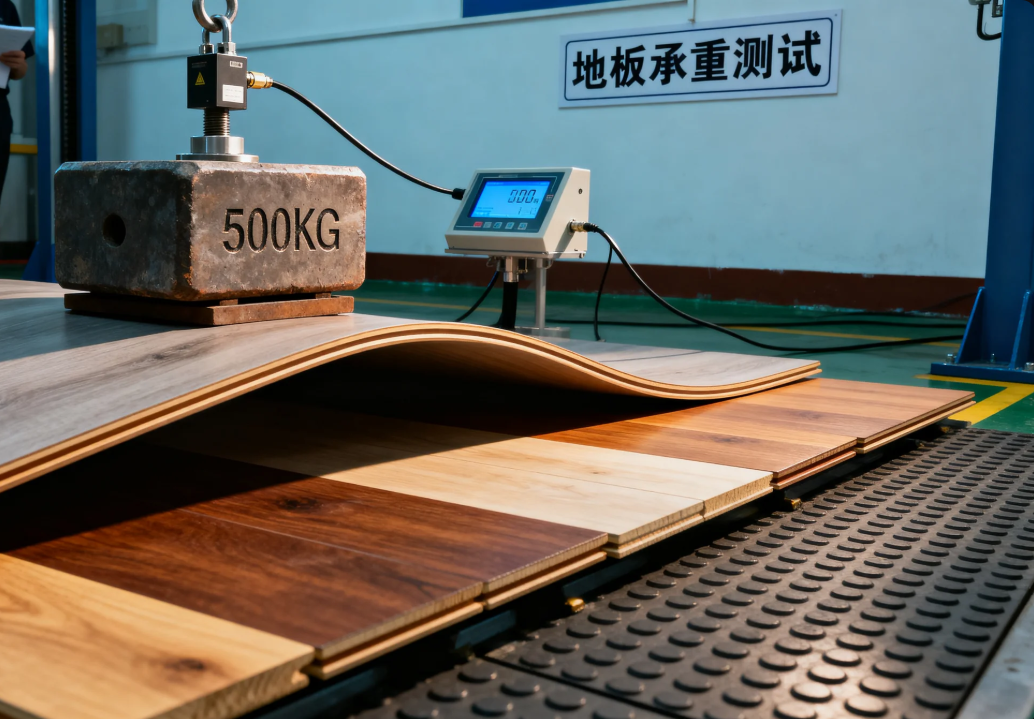

3. What is the load-bearing capacity of the three-layer floor?

A standard three-layer floor can have a static load capacity of 500-800kg/㎡ and a dynamic load capacity (while driving) of approximately 300-500kg/㎡. The actual load capacity needs adjustment based on the food truck's layout, for instance, localized reinforcement is needed under cooking ranges. It is recommended to keep the load rate within 70% of the design value to extend service life.

4. What material options are available for the three-layer floor?

Oriental Shimao Food Truck Company offers various customization options:

Surface Layer: Stainless steel, anti-slip patterned aluminum plate, food-grade coated steel plate

Middle Layer: Bamboo-wood composite board, polymer, fire-resistant rock wool

Bottom Layer: Galvanized sheet, FRP (Fiber Reinforced Plastic, for corrosion resistance)

Enhanced anti-rust or sealing processes can be selected based on regional climate (e.g., coastal high-humidity environments).

5. Is the maintenance cost for the three-layer floor high?

Daily maintenance for the three-layer floor only requires cleaning the surface and periodically checking seam seals. If local damage occurs, individual modules can be replaced without full disassembly. Long-term maintenance costs are lower than traditional single-layer floors, with average annual maintenance costs accounting for about 1-3% of the initial cost.

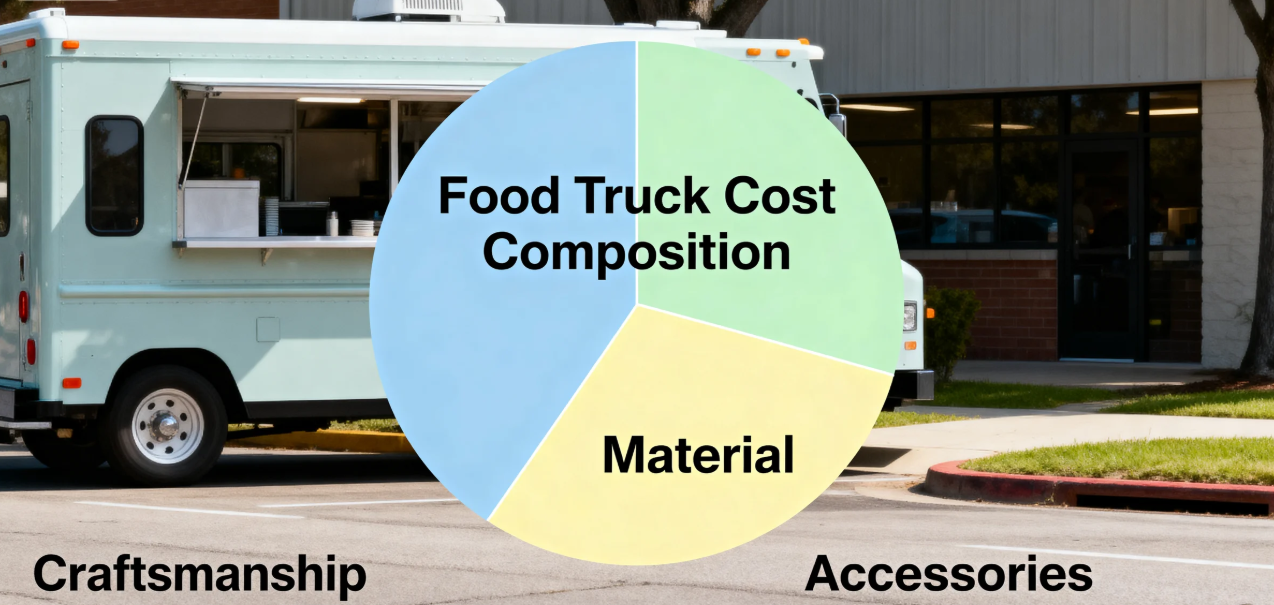

6. What is the approximate cost for a custom three-layer floor?

The price for a basic three-layer floor (suitable for a 3-meter long food truck) starts from approximately $1,150 - $1,700. The final cost depends on materials, craftsmanship, and component brands. For instance, adding an insulation layer or anti-slip upgrades may increase the cost by 10-20%.

7. How to choose a food truck with a three-layer floor?

Oriental Shimao Food Truck Company offers one-stop solutions:

Recommending floor structures based on operational scenarios (e.g., fire-resistant materials for frying trucks)

Supporting custom designs based on drawings, adapting to existing vehicle modifications

Providing material samples and load-bearing test reports to ensure compliance

Conclusion

The three-layer floor is a core design that enhances the durability and safety of food trucks. Oriental Shimao Food Truck Manufacturing Company provides reliable support for mobile catering entrepreneurs through material innovation and modular processes. Contact us for your customized solution!

Note: The data in this article is based on industry standards and company product parameters; specific designs are subject to actual requirements.